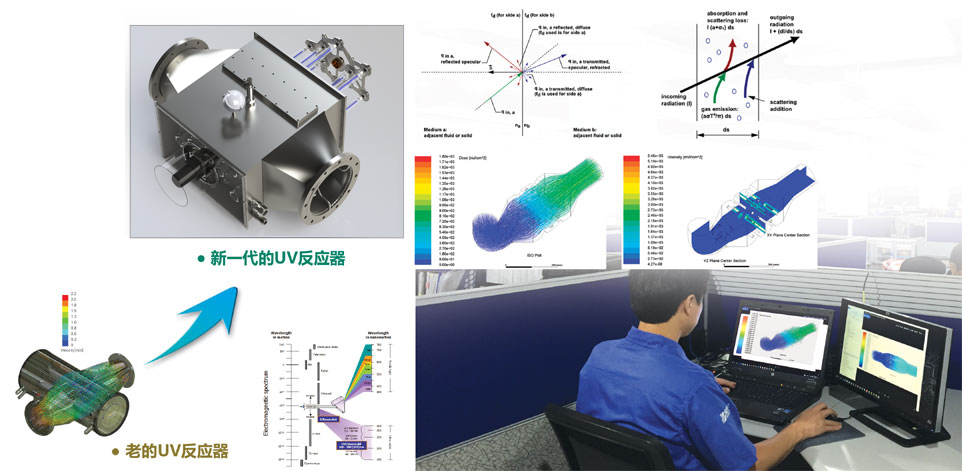

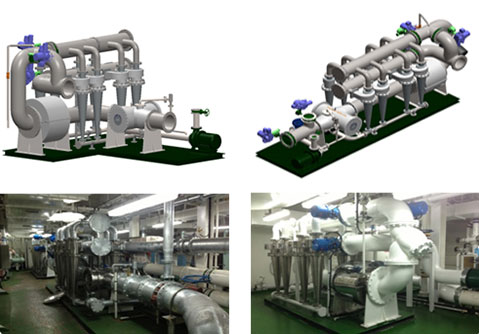

BSKY owns a batch of scientific research teams with international professional level on ballast water treatment device, system is designed through computer fluid dynamics (CFD) calculation and several biological ID test through computer simulation (liquid flow pattern, light distribution, etc.), many biological tests and verifications meet USCG test standard and IMO new G8 standard. Professional design of efficient UV disinfection and management systems, including UV power and control system.

More advanced UV reactor design

Through simulating every drop of water in UV reactor (take grid with diameter of 50um pixel) to obtain consistent UV radiation energy, our new generation UV reactor has the RED (Reduction Equivalent Dose) energy effect 1.45 times higher than the former UV reactor on UV energy utilization. At the same time, this reactor has passed USCG and IMO NEW G8 type test and obtained satisfactory result.

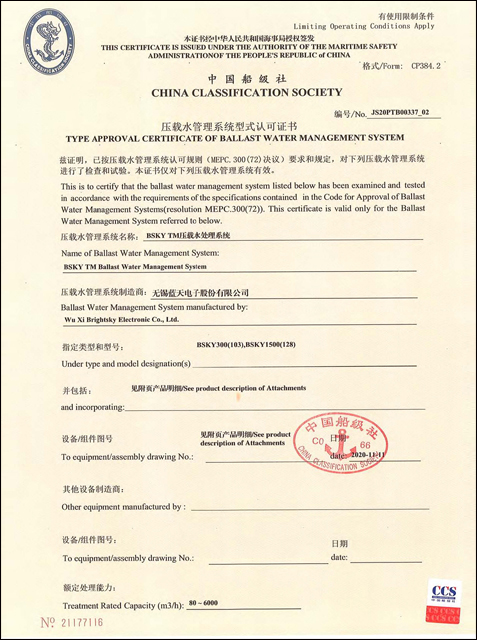

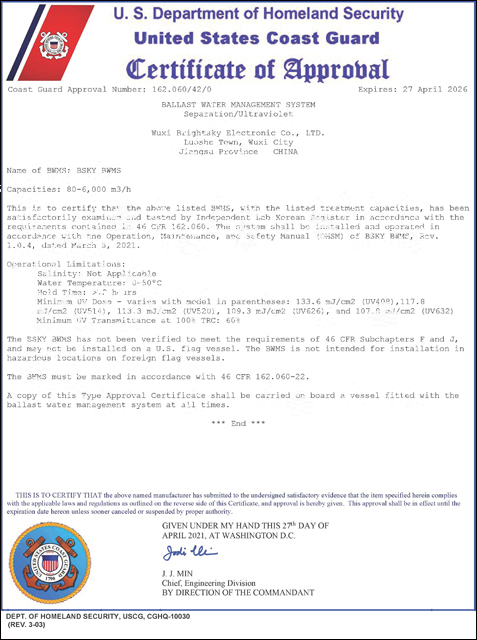

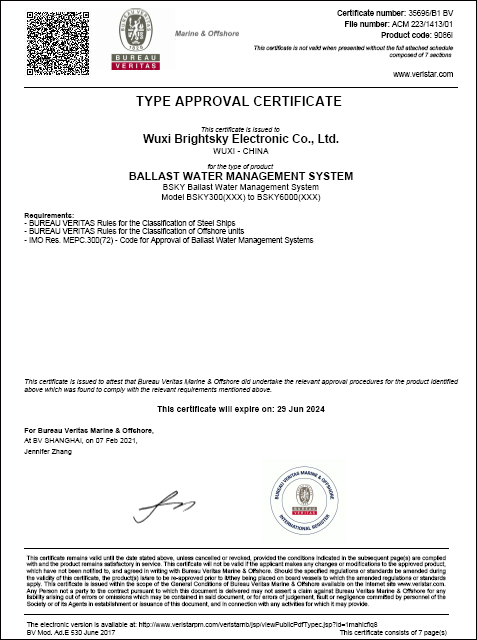

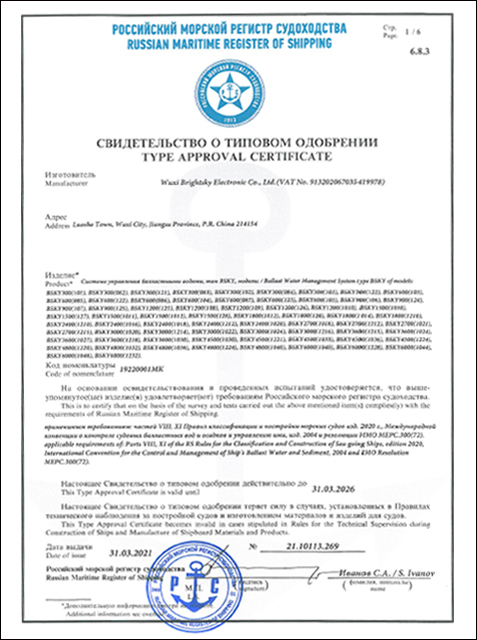

BSKY BWMS have gained global type approvals such as CCS, USCG, BV, KR, RS, RINA, LR; and DNV, PRS, NK is in progress.

BSKYTM BWMS have been installed on vessels around the world,262 vessels are Chinese owner,71 vessels are Japan, 49 vessels are Germany, 33 vessels are Singapore, 32 vessels areTurkey,18 vessels are Bengal,and 95 vessels are other countries. Total reference is 560 vessels and 272 vessels are to new vessel, 288vessels are to retrofit vessel.

Installation Reference ( New vessel 272 )

| Ship Owner | China | Malaysia | Singapore |

| Ship Type | Bulk Carrier | 7K PC | LPG Carrier |

| Pump Capacity | 1000m³ / h x 2 | 200m³ / h x 2 100m³ / h x 2 |

300m³ / h x 2 |

| Model | BSKY1000x2 set Skid Type |

BSKY400EX x 1 BSKY100 x 1 |

BSKY300 x 1 set Skid Type |

| Installation Location | Engine Room | Pump Room Engine Room |

Engine Room |

| Shipyard | China | China | Japan |

| Class | DNV | ABS | BV |

|

|

|

| Ship Owner | Korea | Japan | Singapore |

| Ship Type | Container | Cement Carrier | LPG Carrier |

| Pump Capacity | 300m³ / h x 2 | 200m³ / h x 2 | 300m³ / h x 2 |

| Model | BSKY300 x 1 set Semi Skid Type |

BSKY 400 x 1 Skid Type |

BSKY300 x 1 set Skid Type |

| Installation Location | Engine Room | Engine Room | Engine Room |

| Shipyard | Korea | Japan | Japan |

| Class | KR | NK | BV |

|

|

|

| Ship Owner | Germany | Germany | Greece |

| Ship Type | Container | Bulk Carrier | LEG Carrier |

| Pump Capacity | 500m³/ h x 2 | 700m³/ h x 2 | 150m³/ h x 2 |

| Model | BSKY500 x 1 set Skid Type |

BSKY 700 x 2 Skid Type |

BSKY250 x 1 set Skid Type |

| Installation Location | Engine Room | Engine Room | Engine Room |

| Shipyard | China | China | Korea |

| Class | GL | LR | DNV |

|

|

|

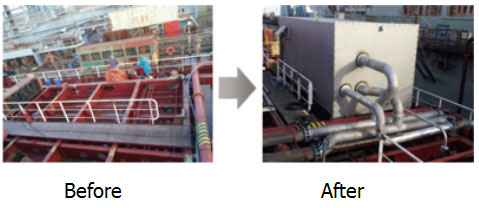

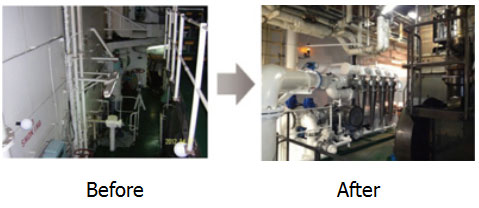

实船安装案例 ( 改造船 288 )

|

|

|

|

|

|

|

|

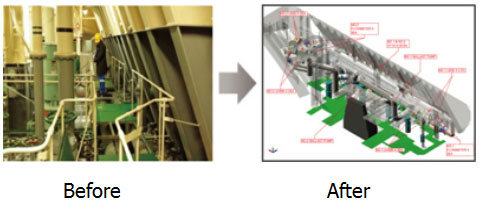

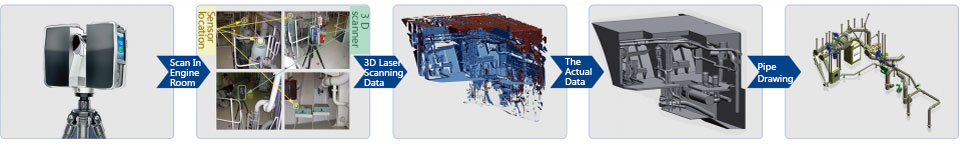

Reverse engineering technology (3D Scanning) can improve the accuracy of locating the parts and pre-fitting of pipes during the installation of BWMS for ships in service,also it has the advantage of saving the time and the waste of the pipes.

| No. | Division | Country | Company | Information | |||

| PIC | TEL. | System | |||||

| 1 | Europe | Turkey | YAF Diesel | Yusuf Kanici | +902164944902 | [email protected] | BWMS |

| 2 | Netherlands | I&C Services B.V. | Fausto Tumolo | 31(0)786913000 | [email protected] | BWMS | |

| 3 | Netherlands | Neohance Automation Solutions | Sjoerd Bearda | 31(0)857606236 | [email protected] | BWMS | |

| 4 | UK | Marine Devision | Slava Kirdejevs | +44 7384651193 | [email protected] | BWMS | |

| 5 | Germany | Maresystems Gmbh | Michael Steinbach

Malte Jaschsk |

+49 4089727330

+49 43216025313 |

[email protected]

[email protected] |

SPARE PART | |

| 6 | C-V Service Co., LTD | Mrs. Cao | +86 15900596239 | [email protected] | BWMS | ||

| 7 | Poland | Marine Technical Service Ltd. | Andrzej Krakowiecki | +48 918524818 | [email protected] | BWMS | |

| 8 | Executive Solutions Group | Grzegorz Guziński | +48 739906378 | [email protected] | BWMS FAS VDR |

||

| 9 | Ukraine | SIF-SERVICE LTD. | Andriy Rodionov | +380 676243346 | [email protected] | BWMS | |

| 10 | Greece | AMS | Emmanuel Azchariakis | +30 210 9627185 | [email protected] | BWMS FAS VDR |

|

| 11 | Italy | Techservice SRL | Magnoni Marco | +39 071 9989887 | [email protected] | BWMS | |

| 12 | Russia | Balhash-Electra | Valentin Sokurenko | +79644335060 | [email protected] | BWMS FAS VDR |

|

| 13 | Australia | Australia | HY-Shipping Marine Service limited | Mr.ren | +86 13817061760 | shasha.ren@huangyueshipping .com | BWMS/FAS/VDR |

| New Zealand | |||||||

| 14 | America | USA | Eversailing Marine Safety Technology (USA) LLC | Jingcai Qiu | 504-4726334 | [email protected] | BWMS FAS VDR |

| 15 | Breakwater International | Dieter Liebich(LA)

Hans Haneveld(Texas) |

+1 3105181718

+1 8325827547 |

[email protected], [email protected]

[email protected] |

BWMS FAS VDR |

||

| 16 | Canada | ALBION MARINE SOLUTIONS | Richard Tang | +1 6045298488 | [email protected] | BWMS | |

| 17 | Brazil | Mapamar comericio e servicos ltda | Castello Branco | +55 2132952600 | [email protected]

[email protected] [email protected] |

BWMS FAS VDR |

|

| 18 | Africa | Ghana | MRS TECH TEMA LIMITED | SHUYAN TANG | +233-547952268 +8613589206970 | [email protected] | VDR |

| 19 | South Africa | Swazi Marine (Pty) Ltd | Ntuthuko Kubeka | +27 413645043

+27 718662263 |

[email protected] | VDR | |

| 20 | Asia | India | Marintech safety and shipping corporation | Hiteshkumar Bamnolia | +91 2240168680 | [email protected] | BWMS FAS VDR |

| 20 | HY-Shipping Marine Service Limited | Ms.Ren | +86-13817061760 | [email protected] | BWMS/FAS/VDR | ||

| 21 | Vietnam | Pegasus Maritime & Development Corp. | Hua Vi Quang | +84 2837734974 | [email protected] | BWMS FAS VDR |

|

| 22 | Malaysia | Unitra Maritime Co. Ltd / FPS Marine Ltd. | Zhang Xia | (JP) +81 7044936487

(CN) +86 13482428356 |

[email protected]

[email protected] |

BWMS | |

| 23 | VT Global Marine Engineering Pte Ltd | Mrs.Lin | +86 18602601729

+65 91789058 |

[email protected] | BWMS | ||

| 24 | Indonesia | Unitra Maritime Co. Ltd / FPS Marine Ltd. | Zhang Xia | (JP) +81 7044936487 (CN) +86 13482428356 |

[email protected] [email protected] |

BWMS | |

| 25 | Japan | Unitra Maritime Co. Ltd / FPS Marine Ltd. | Zhang Xia | (JP) +81 7044936487 (CN) +86 13482428356 |

[email protected]

[email protected] |

BWMS | |

| 26 | Kamome boueki co.,ltd | Li Xing Shen | +86-13501683420 | [email protected] | VDR | ||

| 27 | Singapore | Seadragon Technologies Pte Ltd | Wilson Wang | +65 63165830 | [email protected] | BWMS FAS VDR |

|

| 28 | Korea | Panstar Tech Solution Co., Ltd. | TG Kim | +82 512408892 | [email protected] | BWMS | |

| 29 | Wigo Corporation | Daniel Woo | +82 1093086393 | [email protected] | BWMS VDR |

||

| 30 | Thailand | Brilliant Performance Co., Ltd | Sompoj L. | +662 4530786 | [email protected] | BWMS VDR |

|

| 31 | Vietnam | VINA TD CO..LTD | Ms.May | + 84 2253880918 | [email protected] | BWMS | |

| 32 | China | Wuxi Brightsky Electronic Co., Ltd. | Hank Cheung | +86 51083316683 | [email protected] | BWMS FAS VDR |

|

| 33 | Middle Asia | UAE | Metromac | Lijesh C K | +971 45636100 | [email protected] | FAS VDR |

| 34 | Fortune Tree Shipping DMCC | Capt. Li Zhengtao | +971 506281173 | [email protected] | BWMS VDR |

||

| Location: Turkey |

| Company: YAF Diesel

PIC: Yusuf Kanici TEL: +902164944902 E-mail: [email protected] |

| Location: Netherlands |

| Company: I&C Services B.V.

PIC: Fausto Tumolo TEL: 31(0)78 691 30 00 E-mail: [email protected] |

| Location: Netherlands |

| Company: Neohance Automation Solutions

PIC: Sjoerd Bearda TEL: 31(0)85 76 06 236 E-mail: [email protected] |

| Location: UK |

| Company: Marine Devision

PIC: Slava Kirdejevs TEL: +44 7384651193 E-mail: [email protected] |

| Location: Germany |

| Company: Maresystems Gmbh

PIC: Michael Steinbach PIC: Malte Jaschsk TEL: +49 40 89727330 TEL: +49 4321 602 5313 E-mail: [email protected] E-mail: [email protected] |

| Location: Germany |

| Company: Location: C-V Service Co., LTD

PIC: Mrs. Cao TEL: +86 15900596239 E-mail: [email protected] |

| Location: Poland |

| Company: Marine Technical Service Ltd.

PIC: Andrzej Krakowiecki TEL: +48 91 852 4818 E-mail: [email protected] |

| Location: Poland |

| Company: Executive Solutions Group

PIC: Grzegorz Guziński TEL: +48 739 906 378 E-mail: [email protected] |

| Location: Ukraine |

| Company: SIF-SERVICE LTD.

PIC: Andriy Rodionov TEL: +380 67 624 33 46 E-mail: [email protected] |

| Location: Greece |

| Company: AMS

PIC: Emmanuel Azchariakis TEL: +30 210 9627185 E-mail: [email protected] |

| Location: Italy |

| Company: Techservice SRL

PIC: Magnoni Marco TEL: +39 071 9989887 E-mail: [email protected] |

| Location: Russia |

| Company: Balhash-Electra

PIC: Valentin Sokurenko TEL: +79644335060 E-mail: [email protected] |

| Location: Australia |

| Company: Timeships Pty Ltd

PIC: Mr. SHEN TEL: +86 13901593672 E-mail: [email protected] |

| Location: USA |

| Company: Eversailing Marine Safety Technology (USA) LLC

PIC: Jingcai Qiu TEL: 504-4726334 E-mail: [email protected] |

| Location: USA |

| Company: Breakwater International

PIC: Dieter Liebich(LA) PIC: Hans Haneveld(Texas) TEL: +1 310 518 1718 TEL: +1 832 582 7547 E-mail: [email protected], [email protected] E-mail: [email protected] |

| Location: Canada |

| Company: ALBION MARINE SOLUTIONS

PIC: Richard Tang Tel: +1 (604) 529 8488 E-mail: [email protected] |

| Location: Brazil |

| Company: Mapamar comericio e servicos ltda

PIC: Castello Branco TEL: +55 21 3295 2600 E-mail: [email protected] E-mail: [email protected] E-mail: [email protected] |

| Location: Ghana |

| Company: MRS TECH TEMA LIMITED

PIC: SHUYAN TANG TEL: +233-547952268 TEL: +8613589206970 E-mail: [email protected] |

| Location: South Africa |

| Company: Swazi Marine (Pty) Ltd

PIC: Ntuthuko Kubeka TEL: +27 41 364 5043 TEL: +27 71 866 2263 E-mail: [email protected] |

| Location: India |

| Company: Marintech safety and shipping corporation

PIC: Hiteshkumar Bamnolia TEL: +91 22 40168680 E-mail: [email protected] |

| Location: Vietnam |

| Company: Pegasus Maritime & Development Corp.

PIC: Hua Vi Quang TEL: +84 28 3773 4974 E-mail: [email protected] |

| Location: Malaysia |

| Company: Unitra Maritime Co. Ltd / FPS Marine Ltd.

PIC: Zhang Xia TEL: (JP) +81-70-4493-6487 TEL: (CN) +86-13482428356 E-mail: [email protected] E-mail: [email protected] |

| Location: Malaysia |

| Company: VT Global Marine Engineering Pte Ltd.

PIC: Mrs.Lin TEL: +86 18602601729 TEL: +65 91789058 E-mail: [email protected] |

| Location: Indonesia |

| Company: Unitra Maritime Co. Ltd / FPS Marine Ltd.

PIC: Zhang Xia TEL: (JP) +81-70-4493-6487 TEL: (CN) +86-13482428356 E-mail: [email protected] E-mail: [email protected] |

| Location: Japan |

| Company: Unitra Maritime Co. Ltd / FPS Marine Ltd.

PIC: Zhang Xia TEL: (JP) +81-70-4493-6487 TEL: (CN) +86-13482428356 E-mail: [email protected] E-mail: [email protected] |

| Location: Japan |

| Company: Kamome boueki co.,ltd

PIC: Li Xing Shen TEL: +86-13501683420 E-mail: [email protected] |

| Location: Singapore |

| Company: Seadragon Technologies Pte Ltd

PIC: Wilson Wang TEL: +65 63165830 E-mail: [email protected] |

| Location: Korea |

| Company: Panstar Tech Solution Co., Ltd.

PIC: TG Kim TEL: +82 51 240 8892 E-mail: [email protected] |

| Location: Korea |

| Company: Wigo Corporation

PIC: Daniel Woo TEL: +82 10 9308 6393 E-mail: [email protected] |

| Location: Thailand |

| Company: Brilliant Performance Co., Ltd

PIC: Sompoj L. TEL: +662 4530786 E-mail: [email protected] |

| Location: Vietnam |

| Company: VINA TD CO..LTD

PIC: Ms.May TEL: + 84 2253880 918 E-mail: [email protected] |

| Location: China |

| Company: Wuxi Brightsky Electronic Co., Ltd.

PIC: Hank Cheung TEL: +86 510 8331 6683 E-mail: [email protected] |

| Location: UAE |

| Company: Metromac

PIC: Lijesh C K TEL: +971 4 5636100 E-mail: [email protected] |

| Location: UAE |

| Company: Fortune Tree Shipping DMCC

PIC: Capt. Li Zhengtao TEL: +971 50 628 1173 E-mail: [email protected] |

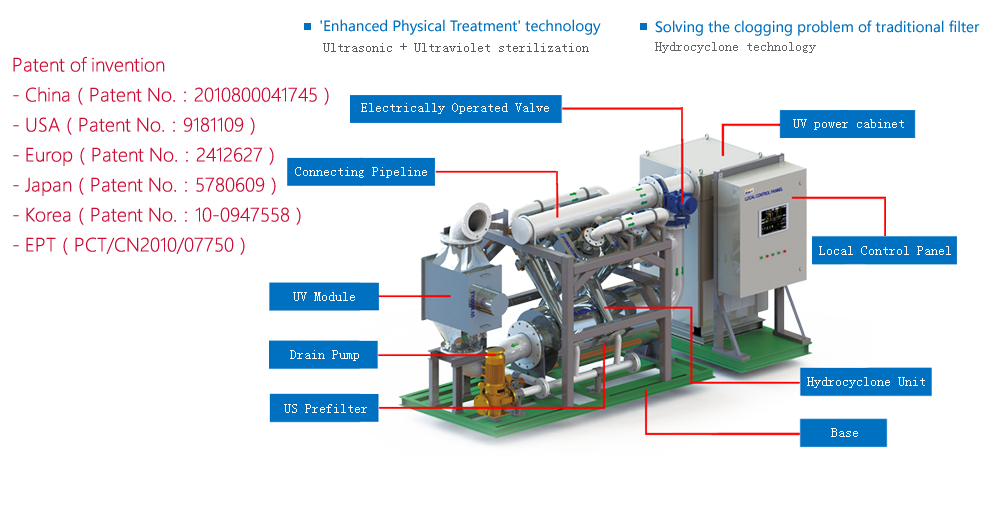

| System Certification | China Important New Products Certificate |

| High-Tech Product Certificate | |

| Patent for Invention in Europe (Patent No. 2412627) | Patent for Invention in the United States (Patent No. 9181109) |

| Patent for Invention in Japan (Patent No. 5780609) | Patent for Invention in Korea (Patent No. 10-0947558) |

| Patent for Invention in China (Patent No. 2010800041745) | EPT International invention patent (NO. : PCT / CN2010 / 07750) |

COPYRIGHT © 2018 Wuxi Brightsky Electronic Co.,Ltd. ALL RIGHT RESERVED.

ICP 11076333-1